3A PLUS® Panel.

- Categories:Products

- Time of issue:2020-02-13 00:00:00

- Views:0

Introduction of 3A PLUS®

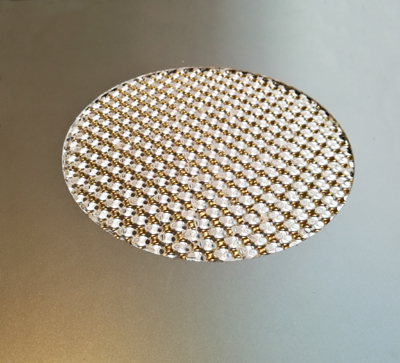

3A PLUS® is compounded by three layer Aluminum sheets. Top Aluminum sheet is coated with excellent weather resistance TiO2 coating or PVDF coating as decoration and protective finish, Middle Aluminum sheet is processed into both sides interlaced, evenly arrangement hollow and trapezoid column overhanging block with concave-convex, Bottom Aluminum sheet is cleaned completely and made chemosynthesis treatment on the surface.

3A PLUS® is compounded by three layer Aluminum sheets. Top Aluminum sheet is coated with excellent weather resistance TiO2 coating or PVDF coating as decoration and protective finish, Middle Aluminum sheet is processed into both sides interlaced, evenly arrangement hollow and trapezoid column overhanging block with concave-convex, Bottom Aluminum sheet is cleaned completely and made chemosynthesis treatment on the surface.

3A PLUS® adopts full dimensions 3 layer structure and continue to use our special mature bonding technology, the attenuation rate of peeling strength is less than 5% within 20 years.

3A PLUS® combines the advantages of several kinds of metal composite panel. It possesses excellent evenness, light weight and high strength, small change rate of compression resistance, unique texture, outstanding weather resistance, easy to process, superior fire resistance, high depreciation recovery rate etc.

Since 3A PLUS® adopts unique edge folding at the corner structure, not only improved bending resistance, wind-load resistance and fatigue life of cyclic loading of materials, but also further increased waterproof, anti-corrosive, penetration resistance and working life of curtain wall.

Since 3A PLUS® adopts unique edge folding at the corner structure, not only improved bending resistance, wind-load resistance and fatigue life of cyclic loading of materials, but also further increased waterproof, anti-corrosive, penetration resistance and working life of curtain wall.Basic parameters

Basic Materia: Metal Aluminum Panel

Coating: TiO2 coating ( PVDF coating or wood-like film are available if choose other colors)

Color:Several standard colors (color chart for 3A PLUS®) 30 kinds of non standard colors are also available (refer to color chart of ALUTILE Aluminum Composite panel)

width:1220mm, 1570mm (Max.)

Length:2440mm or as per client’s request.

Thickness:3mm, 4mm or 6mm

Fire Class: excellent fireproof resistance for A2 Class

Application scope :Metal Curtain Wall, Interior wall integrated panel, Public building’s over length strip (≥6m) for ceiling, Functional special panels(Engine room, Operating theatre), special panel for internal cabins of boat.

Advantage of 3A PLUS®

The comparsion of characteristics between 3A PLUS® and other metallic cladding materials

| Performance | Aluminum Composite Panel | Solid Aluminum Panel | Aluminum Honeycomb Panel | 3A PLUS® |

|---|---|---|---|---|

| structure type | Sandwich structure, the LDPE middle layer is combined with upper and lower alloy aluminum plates. | All aluminum structure | All aluminum structure | All aluminum structure |

| Resistance to wind pressure deformation |

★★★★ Low wind pressure deformation rate |

★★★ High resistance to wind pressure deformation |

★★★★★ Low wind pressure deformation rate |

★★★★★ Low wind pressure deformation rate |

| Structural safety |

★★★ High weight to rigidity ratio |

★★★★★ High structural strength |

★★★★ High weight to rigidity ratio |

★★★★★ The VA non-toxic unique bridge bonding composite process makes the peel strength high, and the weight-to-rigidity ratio is comparable to that of aluminum honeycomb panels. |

| Face value index |

★★★★★ The flatness of the board is excellent, the continuous roll coating process, the color is even. |

★★★ The flatness of the board is poor, and the color difference of the spraying process is difficult to control. |

★★★★ The flatness of the board is good, and the panel is coated with rollers. |

★★★★★ The flatness of the board is excellent, the continuous roller coating process has uniform color and small color difference, and realizes the coating effect that is difficult to achieve by the spraying process. |

| Fire performance |

★★ Fire class B, used in high-rise buildings is subject to certain restrictions. According to the existing production process technology, if the fire rating is to be increased, the interlayer peel strength will be reduced. |

★★★★★ Class A2 non-combustible |

★★★★ A2 grade non-combustible, solvent-based adhesive process reduces fire performance |

★★★★★ Non-combustible with fire rating up to A2 |

| Environmental Protection Index |

★★★★ Energy saving, environmental protection, recyclable |

★★★★ Recyclable and cost-effective |

★★★ Adhesive technology, solvent evaporation |

★★★★★ Material saving, energy saving and environmental protection |

| Post-processability |

★★★★ High production efficiency and excellent post-processing performance. |

★ With many solder joints, labor-intensive and low production efficiency, it is a double-high product. |

★★★ The production efficiency is low, the riveting strength of the post-processed folding corner is poor, and it is easy to collapse. |

★★★★★ The production efficiency is high, and the post-processing performance is better than aluminum-plastic plate. |

| other | The export codes are listed separately and belong to new material products encouraged by the state. | Building curtain wall panel replacement product integrating multiple product advantages |

Application Scope

3A PLUS® is widely used in airport, high-speed railway, metro, light rail, museum, archives center, conference and exhibition center, commercial complexes, high-grade office buildings, hotels and other public buildings and commercial buildings for high-end metal wall decoration.

* First choice for functional-requirement machine room, medical operating room, precise instrument room, database's interior and exterior decoration;

* Special decoration for High-Speed railway's carriage, yacht, ship's interior decoration.

Scan the QR code to read on your phone

0086 13576919560

TOP

GAN ICP15001297 © 2020 ALUTILE. All Rights Reserved.