1. The Decorative Layer of Surface

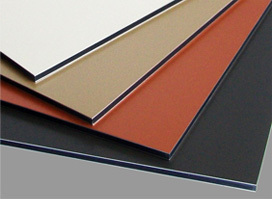

Nowadays the decorative layer for metal substrate mainly includes all kinds of coating, film, surface transformation etc.

1. Paint Coating

|

Types: |

Acryloyl ( AC ) SDPE |

Silicon Modified Polyester ( SMPE ) Epoxide |

Polyester ( PET ) Urethane ( PV ) |

Polyester Amide ( PA ) PVDF |

Why PVDF coating possesses so excellent performances ?

The structure combined fluorin-carbon short bond with hydrogen bond is steadiest and firmest structure among all kinds of chemical structure at present. As the criterion of judging stability and fasten of structure, the electronegativeatom index reaches 105 kilojoule/mole. For normal coating, it is just 83.2 kilojoule/mole for energy of normal carbon and carbon combination.

There is an inorganic material whose constituent is SiO2. It is created by chemical method and composed of pure inorganic resin. As the energy of composing Silicon and Oxides is 101 kilojoule/mole, this kind of unite cannot be destroyed by ultraviolation in sunshine.

Moreover, performances of this coating, such as contamination resistance, incombustibility, and environmental protection are very excellent.

The Coating of ALUTILE® Exterior Composite Curtain-Wall Panel

Generally speaking, the higher content of PVDF and better weather resistance, the poorer adhesive force. ALUTILE® panel selects a scientific arrange in pairs or groups for PVDF coating. The percent of PVDF in prime paint is low, but the adhesive force is good so that the prime paint can adhere to the base material very well. Strictly speaking, it creates a layer thermoplastic PVDF coating, which possesses very excellent performance of Mek resistance.

1.General Properties

| Dry Film Property | Test Method | Criteria |

| 60°Gloss | ASTM D 523-89 | 20% to 75% |

| Form a bily(T-bend) |

ECCA 11-19 ASTM D 1737-62 |

2T,no cracking |

|

Reverse Impact-Crosshatch |

ECCA 11-5 | No pick off |

| Pencil Hardness | ASTM D 3363-92a | 3H |

|

Adhesion: Dry Wet Boiling Water |

ASTM D 3359. Method 8 37.8℃, 24hrs. 100℃, 120min |

No change No change No change |

| Abrasion Resistance |

ASTM D 968-93 (Fall ngs and) |

20liters/milas the criterion of AAMA, 70 liters/milas the actual value |

|

Chemical Resistance: HCI H2SO4 Mortar Detergent |

ASTM D 1308-79 ASTM D 1308-79 AAMA 605.2-90 ASTM D 2248-73 |

No change No change No change No change |

2. Weather ablity

| Dry Film Property | Test Method | Criteria |

| Color Retention | ASTM D 2244-93 | Max. 5 units; after 4000hrs |

| Gloss Retention | ASTM D 523-89 | 70% after 4000hrs |

| Chalking | ASTM D 4214-89 | Max. 8 units; after 4000hrs |

| Salt Spray |

ASTM D-B 117-90 ECCA 11-2 |

Blisters -10; Scribe-8 3000hrs; aluminium,35℃ |

| Humidity-Therma | ASTM D 2246-65 | No blister; No cracking; 10 cycles :2; 4hrs.*100%; RH,37.8℃:; 2hrs.*18℃; 4hrs.*24℃ |

| Humidity | ASTM D 2247-94 | No change; 3000hrs.; aluminium 35℃ |

The PVDF coating thickness can be measured by the enlarged cross-section diagram, the left drawing is a magnified 4000 times photograph. It can be calculated the coating thickness from the measuring tape: PVDF Prime 5~7 microns, PVDF varnish paints 20~23 microns. Such PVDF Coating arrangement is very reasonable, but in order to reduce the cost, some inferior panels are made by means of increasing the prime thickness and reducing the thickness of PVDF

2. Sticking Film

A layer of decorative film ( such as PVC, PE film ) is sticked to the surface of base material. Some kinds of films are fallen into disuse because of poor weathering resistance. PET film, a kind of high performance polyester film, is a very thin layer of polyester coating on the surface of base material, then adheres to the polyester coating through continuous thermal plying method. There are many kinds of styles, and it can imitate all kinds of material, such as marble and nature lumber etc. PET is more and more popular due to its excellent weathering resistance, compared with normal organic coating transform of surface.

3. Sticking Film

A kind of anti-corrosion transform coating is created on the surface of metal by chemical method. Its performance is more and more excellent along with technology improving. Especially for a kind of porcelain oxidation, there is a compact oxidation layer A1203 on the surface of aluminium. The hardness of surface is very strong with excellent scuff resistance and abrasion resistance, and it can be used for decorating floor and possesses the excellent weathering resistance performance. The potential market is very big.

Hongtai Group can supply the above curtain-wall materials with the several decoration coatings.

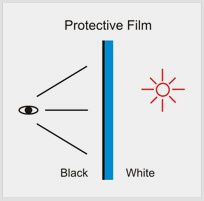

2. Protective Film

The protective film protects panel from mechanic damage and contamination when cutting, transiting, grooving and folding After finishing installation, protective film will be peeled off.

ALUTILE® panels adopt the first-grade quality protective film supplied by France and Germany.

● Basic film material: Double PE

The retardation performance is good; weathering resistance is better than PVC.

● Structure type: Inner in black, outer in white

High cost, with excellent weathering resistance and stable bond performance. The glue rarely remains on the panel surface.

● Glue type: Rubbe

White outer, black inner, Black prevents ultraviolation and white reflects ultraviolation, the retardation performance and protection of glue film is excellent.

Distinguish protective film quality:

Film thickness > 0.08mm, black inner and milky white outer

● According to the graph, the transparency degree of protective film should be very low.

● The voice generally is low when tearing off the film with rubber layer, string is long and white, the gloss of rubber layer is low.

● The voice generally is high when tearing off the film with acryloyl layer, string is very short and the gloss of rubber layer is high.

● The above-mentioned is only for reference. It can not be the final judgment, as it must be tested by advanced instrument.

3. Core Materials

There are mainly two kinds of core materials for ALUTILE® Composite Panel: Polyethylene core for Aluminium Composite Panel, un-flammable Nano rubber-plastic core for Fire-Resistance Aluminium Composite Panel .

1. Core Materials of ALUTILE® Aluminium Composite Panel

ALUTILE® Aluminium Composite Panel adopts polyethylene core materials that mix high quality extrusion-grade, LDPE and L-LDPE. It possesses excellent properties, such as easy processing, chemical resistance and mechanic performance and avoids the weakness (contraction ratio too soft and too high longitudinal ). So ALUTILE® Panels keep even when exposed to the heat of tropical or the cold of frigid snowstorm.

2.Core Material of ALUTILE® Fire-Resistance Aluminium Composite Panel

It is a new-type core material, which is independent developed by our company. It is alloy outcome of inorganic nano material and many kindly of high molecular material; the oxygen index is very high. It possesses excellent weathering resistance and mechanic performance. It not only break through the technical problem that normal Aluminium Composite Panel is not fireproof, but also greatly improves the dynamics performance of folding position, which is the weakness of normal Aluminium Composite Panel. It can be applied in more fields and made possible to use in higher building due to improved dynamics strength, fatigue property and corrosion-resistance of folding position.

4. High Molecular Adhesive Film

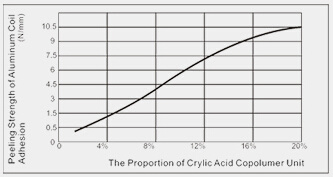

Molecular structure of high molecular adhesive film EAA* ( ethylene-crylic acid copolymer )

Adhesion's principle of high molecular adhesive film

( Crylic acid polar branch can combine with polar metal surface to create hydrogen bond )

EAA* ( ethylene-crylic acid copolymer )

According to the test, the adhesive force reflects the proportion of crylic acid copolymer unit in high molecular adhesive film for Aluminium sheet thickness 0.5mm as the following chart.

The production methods of high molecular adhesive film: glue spraying, glue spreading, radioactive combination, blow mold and two-layer coextrusion etc.

ALUTILE® Nano Rubber Fire-Resistance Aluminium Composite Panel and Aluminium Composite Panel adopt two-layer high molecular adhesive film, one side is dull and another side is slick, crylic acid polar branch of dull face is affinity with metal and slick face has affinity with core material.

Peeling Strength of ALUTILE® Products ( GB/T2790 )