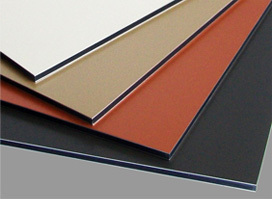

Aluminium Composite Panel

ALUTILE® Aluminium Composite Panel is compounded with top and bottom layers of aluminium sheet, non-toxic polyethylene core materials. Both surfaces are coil coated with special baking varnish.

ALUTILE® Aluminium Composite Panel selects all kinds of domestic materials with superior quality. Both top and bottom aluminum sheet pass strict chemosynthesis treatment and adopt reversal precision coating, short and long wave baking, continuous thermal compound and other advanced production technology.

ALUTILE® Aluminium Composite Panelpeeling strength, panel flatness, and the coating has excellent characteristics, such as evenness, multiple colors, strong adhesion, specially anti-corrosion, weather resistance and anti-pollution.

1. Product Specification

● Standard:

According to China National Standard GB/T 17748-2008

● Specification:

Aluminium sheet thickness:

0.50*0.50mm 0.40*0.40mm 0.30*0.30mm

0.21*0.21mm 0.15*0.15mm

Width: 1220mm, 1570mm ( Maximum )

Length: 2440mm, upon customer's request.

● Standard Size: 1220(Width)*2440(Length)*3mm(Thickness) for interior

1220(Width)*2440(Length)*4mm(Thickness) for exterior

● Normal Color: 30 kinds

Non-standard sizes and special colors are available

according to customers` request.

2. Product Characteristics

● High Peeling Strength ALUTILE® panel is cross linking under high temperature with high-performance and molecular binding materials,which reaches the ideal level for the important feature high peeling strength.

● Superior Weather Resistance By means of KYNAR500 based PVDF coating resin, ALUTILE® panel possesses some superiorities in corrosion resistance, alkali resistance, chalking resistance of ultraviolet light. When exposed to the heat of tropical sunshine or the cold of frigid snowstorm, the panel never loses its colorful appearance.

● Light Weight and Easy to Process ALUTILE® panel is easy to process for its light weight ( 3.5-5.6kg/m2) which can decrease the loss during an earthquake. The processing such as cutting, planning, bending to arc and several configurations in right angle can be done by some simple woodworking tools. Designers can also make the flexibility in the panel. The installation work is going to be easy and fast. For this reason, it can save the cost.

● Excellent Fireproof Property Its core layer is manufactured with Anti-toxic polyethylene core materials, having the combustion resistance property. Two surface layers are made of aluminium, which is difficult to be burnt. Therefore, this is a kind of safe fireproofing materials, complying with the fireproof demand in building code.

● Coating Evenness, Multiple Colors Since applied the chemosynthesis treatment and Henkel technology, the adhesion between the paint and panel becomes evener, having multiple colors. There is more space for your choice to the color with individuality.

● Easy to Maintain The anti-contaminant property has been obviously improved for ALUTILE® aluminium composite panel. Due to good selfcleaning capability, neutral detergent can clean the panel easily even though the pollution is very serious.

● Impact Resistance The impact resistance and toughness are strong. The coating layer can not be crashed when it's bent. The panel can not be damaged when in a strong windy and sandy condition.

3. Product Colours and Surfaces

Authorization center as PPG company, ALUTILE® aluminium composite panel paint coating of excellent performance for the customer to choose:

● PVDF coating: PVDF fluorocarbon paint coating is all comprehensive chemistry excellent. Alice Thai selection America PPG quality of fluorocarbon paint. Suitable for the construction of weathering, acid and alkali resistance, corrosion resistance, air pollution, ultraviolet resistance, stain resistance and high performance requirements of indoor and outdoor decoration.

● Polyester (PET) coating: the persistent performance superior polyester coating has beautiful color, color. At the same time to meet customer requirements for the performance and economy of high quality paint. Suitable for indoor decoration and corporate image display, application identification plates.

● Post pattern roller / film: imitate nature of natural stone, wood and other gang grain effect. In color with a rich, vivid and bright, rich texture, can provide nearly a thousand kinds of marble and wood for the customer to choose a wide range.

● Special effect: to support the implementation of the coating designer ideas, through a variety of color, pearl and other surface effects to enable you to the best way to make the creative inspiration to get the better present.