Fire Resistance Aluminium Composite Panel

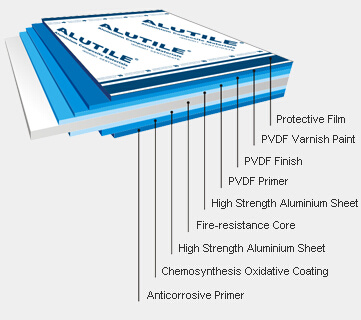

ALUTILE® Fire Resistance Panel is compounded with top and bottom layers of aluminium sheet, inorganic compound flame retardant and nanometer fire-resistant core materials, both surfaces are coil coated with special baking varnish.

1. Basic product parameters

| Standard | According to China National Standard GB/T 17748-2008 |

| Fire Class |

Class A as per ASTM standard Class Oas per BS 476 standard Class 1asperBS 476 standard |

| Specification |

Aluminium sheet thickness: 0.50*0.50mm0.400.40mm0.30*0.30mm0.21*0.21mm0.15*0.15mm Width:1220mm, 1570mm(Maximum) Length:2440mm, upon customers request. |

| Standard Size |

1220(Width) *2440(Length) *3mm(Thickness) 1220(Width) *2440(Length) *4mm(Thickness) |

| Normal Color |

30kinds Non-standard sizes and special colors are available according to customers`request. |

2. Product Specification

Outstanding Fire Resistance Property:

ALUTILE® fire resistance panel has outstanding fire resistance property, the oxygen index of core materials reach more than 44. It has been tested by Intertek, which meet the class A requirement as per ASTM standard and class 0 requirement as per BS standard.

Superior Fabrication:

ALUTILE® fire resistance panel is superior fabrication, which can be processed the same as normal aluminium composite panel or remain 2-3mm in core material thickness. The processing such as cutting, planning, bending to arc and several configurations in right angle can be done by some simple woodworking tools. Designers can also make the flexibility in the panel. The installation work is going to be easy and fast.

Coating Evenness, Multiple Colors:

Since applied the chemosynthesis treatment and Henkel film technology, the adhesion between the paint and panel becomes more evenness, having multiple colors. There is more space for your choice to the color with individuality.

Perfect Cold Temperature Resistance:

The core layer in normal aluminium plastic panel is made from polyethylene, which starts to be brittle at -60℃. After the brittleness, it looks like a glass. Then the brittle point of the core material in fire resistance panel reaches -100℃. So the panel can be used in the frigid area.

High Peeling Strength:

Since applied the chemosynthesis treatment and Henkel technology, the adhesive strength between the paint and panel is strong. Even gloss and varied colors provide customer multiple choices and individuality.

Impact Resistance:

The impact resistance and toughness are strong. The coating layer can not be crashed when it's bent. The panel can not be damaged when in a strong windy and sandy condition.

3. Product Colours and Surfaces

Authorization center as PPG company, ALUTILE® aluminium composite panel paint coating of excellent performance for the customer to choose:

PVDF coating:

PVDF fluorocarbon paint coating is all comprehensive chemistry excellent. Alice Thai selection America PPG quality of fluorocarbon paint. Suitable for the construction of weathering, acid and alkali resistance, corrosion resistance, air pollution, ultraviolet resistance, stain resistance and high performance requirements of indoor and outdoor decoration.

Polyester (PET) coating:

the persistent performance superior polyester coating has beautiful color, color. At the same time to meet customer requirements for the performance and economy of high quality paint. Suitable for indoor decoration and corporate image display, application identification plates.

Post pattern roller / film:

imitate nature of natural stone, wood and other gang grain effect. In color with a rich, vivid and bright, rich texture, can provide nearly a thousand kinds of marble and wood for the customer to choose a wide range.

Special effect:

to support the implementation of the coating designer ideas, through a variety of color, pearl and other surface effects to enable you to the best way to make the creative inspiration to get the perfect present.